Services

Vibration Measurement & Analysis

Vibration Measurement & Analysis

Vibration Analysis

- Rotating machines are among the most critical parts of industrial processes. Monitoring and protection of these machines requires state-of-the-art systems that meet the increasing demands of industrial applications.

- Our expertise is to support the control of these critical sensors and systems throughout their operating lives; to guarantee maximum machine availability and safety and to provide new monitoring data and machine insights.

- Products for machine protection and condition monitoring

Vibro-meter is a Parker Meggitt solution portfolio for critical rotating machine protection and condition monitoring.

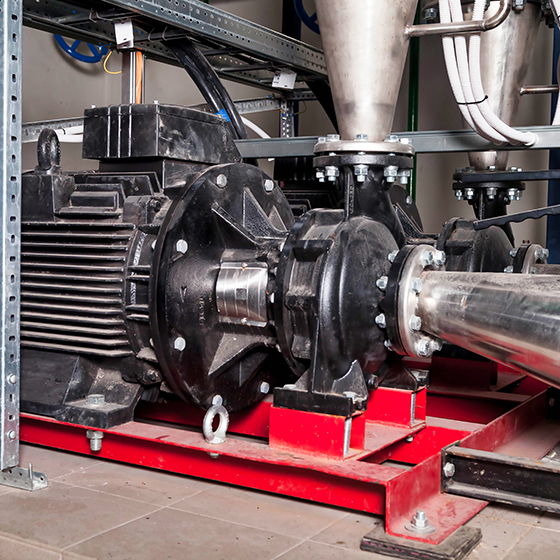

For 70 years, our products and expertise have provided superior solutions for detecting and monitoring vibration, pressure, air gap and other important parameters in critical facilities and equipment.

Trusted by major OEMs worldwide and becoming standard components installed on machines used in Power Generation, Oil & Gas and other industrial applications.

Our comprehensive, high-quality sensor and measurement chains, VM600 rack-based systems, VibroSmart distributed systems, VibroSight system software and Overspeed systems provide end users and OEMs with total solutions to monitor and protect your critical machines and processes.

- Vibro-meter's comprehensive sensor and measurement chain range can be used with our monitoring system hardware and software (or third-party systems) to provide complete solutions for monitoring and protection of critical machines and processes.

From standard to challenging industrial environments, including hazardous areas and/or extreme temperatures (up to 700°C).

- VibroSmart is a family of networkable devices developed for implementing machine protection system (MPS) and/or condition monitoring system (CMS) solutions with low to medium measurement channel density and can be installed wherever needed. VibroSmart enables operators to cost-effectively monitor and protect critical small machines without compromising performance.

- Highly flexible distributed protection and condition monitoring system for turbines, pumps and smaller critical assets requiring low channel count. Modules can be mounted directly on machines, eliminating the need for costly wiring. Modules communicate with each other and VibroSight software in real time via Ethernet and fieldbus.

- Key Benefits

– Reduced installation costs: VibroSmart devices are mounted directly on or near the machine, so operators save up to 30% on installation and wiring costs. The use of standard Ethernet cables helps simplify installation.

– Multi-purpose solution: VibroSmart VSV301 can handle most signal types – vibration, displacement and dynamic pressure. It can be configured to offer unique combinations of MPS and/or CMS functionality.

– As simple or detailed as you need: VibroSmart's modular structure is highly flexible and scalable. A single VibroSmart VSV301 can function as a system on its own or be combined with other VibroSmart devices to provide a network-based monitoring system.

- VibroSight – Machine monitoring system software

Advanced machine protection and condition monitoring system software designed to work with VM600Mk2/VM600 rack-based systems and VibroSmart distributed monitoring systems. VibroSight is fast, powerful and user-friendly software that enables optimization of reliability and operational efficiency of industrial machines through the use of advanced predictive maintenance methodologies.

Need Technical Support?

Our expert team is ready to help with product selection, technical specifications, and custom solutions.

Contact Our Experts