Services

Position Sensing and Management

Position Sensing and Management

Types of position sensors and their applications

Position sensing is a critical function in a wide variety of applications, from robot drive chains to conveyor belts in supply chain operations to swaying of wind turbine towers. It can take many forms including linear, rotary, angular, absolute, incremental, contact and contactless sensors. Specialized sensors have been developed that can determine positions in three dimensions. Position sensing technologies include potentiometric, inductive, eddy current, capacitive, magnetostrictive, Hall effect, fiber optic, optical and ultrasonic.

There are many factors to consider when selecting position sensors. Some examples are:

Position measurements can be linear, rotary or angular, and can be static or dynamic (velocity and/or acceleration measurement).

Linear sensors are usually limited to a specific measurement range, while rotary sensors usually provide measurements in revolutions or degrees.

These sensors can be based on contact or contactless technologies. Contact sensors are usually cheaper, while contactless sensors tend to be more reliable.

The resolver is a special contactless rotary sensor that can provide both position and speed feedback.

Some sensors provide only incremental measurements from one point to another, while others provide absolute position information relative to a specific reference point.

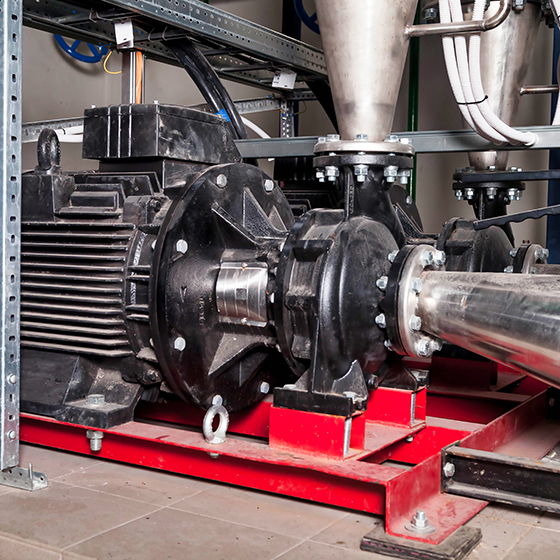

Traditional industrial sensors, whether incremental or absolute, can meet the needs of many general/industrial motion control applications. However, when these devices are placed in operating environments where they are exposed to temperature, high shock and vibration, aggressive contaminants, prolonged immersion in liquids and water vapor, or EMI noise, they are more likely to fail. When traditional sensors fail, downtime costs associated with sensor failure can quickly rise to several times the cost of the sensor itself. Sensor failure ultimately causes extensive damage, especially in the iron and steel industry.

NSD's exceptional durability is achieved through a creative design structure that eliminates contact parts and has zero electronic components inside the sensor, and ABSOCODER has proven excellent durability and extremely long life in the field in the steel production industry.

Need Technical Support?

Our expert team is ready to help with product selection, technical specifications, and custom solutions.

Contact Our Experts