Services

Lubrication Technology

Lubrication Technology

Oil Water Separation (Dehydration Systems)

Especially for solving oil+water problems in central lubrication tanks, NORTEK Fluids Technology in collaboration with Morgan Oil company produces and patents NORTEK Mobile and Fixed Vacuum Dehydration Units to dehydrate unwanted water in your oil, extend your equipment life and prevent unforeseen failures.

NORTEK Fluids Technology Mobile and Fixed Vacuum Dehydration Units have a flow rate from minimum 20 L/Min to maximum 115 L/Min. With its superior performance, it reduces water in your oil by 98%. It can be integrated everywhere thanks to its easy portability. It provides energy saving with energy recovery system. With the water sensor and oil contamination sensor on it, you can monitor and control the amount of water and contamination in the oil at any time with the 12" touch panel on the PLC screen.

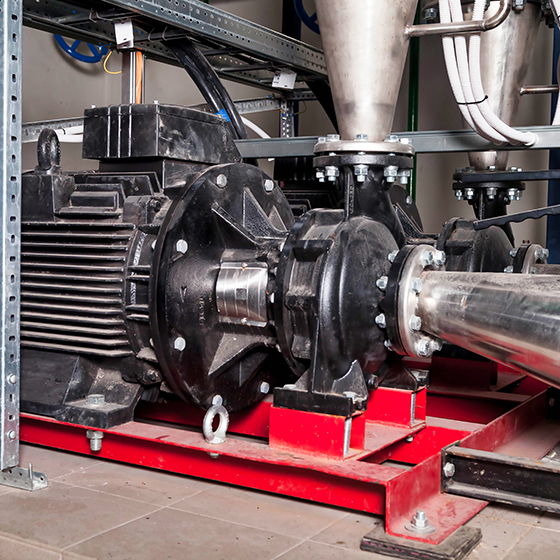

Oil Filtration

PORTABLE FILTRATION SYSTEMS

The Mobile Filtration Unit developed by NORTEK Fluids Technology is designed to monitor particles and water content in oil and filter oil in tanks. The system includes an integrated control panel to set operating time or set the desired ISO code for cleaning. When the desired target is reached, the equipment gives an alarm and stops the unit. It is designed with an air bubble suppression system to prevent measurement errors caused by air bubbles. Different filtration grades are also available. Visual and electrical indicators are available for filter saturation. It has a control panel that allows the operator to set the operating time or set a desired cleanliness value.

Includes water sensor and particle sensors to provide information about water content and ISO or NAS code. Filter elements are interchangeable from different manufacturers, so you won't be tied to a single brand.

Filtration capacity can be designed upon customer request.

MAGNETIC SEPARATORS

In steel processing, cast iron processing and sintering water cleaning, cooling liquids used as well as rolling and polishing liquid are highly susceptible to metal contamination. These foreign metallic objects can affect final product quality, cause continuous failures and cause serious damage to the machine. NORTEK Fluids Technology Magnetic Separators can reduce the concentration of ferritic particles below 70 ppm. Filtration capacity can be designed upon customer request.

Descaling System

Scale on steel surface is formed due to oxidation of the main material during reheating of the billet/material. The descaling system is used to prevent this layer from fusing with the main material during the rolling process. In the Descaling Systems manufactured by NORTEK Fluids Technology company, high-pressure water jet works with perfect performance by removing the loosened scale from the main material through strategically placed nozzles at different angular positions.

Air Oil System

NORTEK Fluids Technology Air-Oil Lubrication Systems reduce the disadvantages created by grease lubrication. It significantly reduces oil consumption. Excess oil can be disposed of more easily than grease. It allows the use of oils of any viscosity and extends the service life of lubricated equipment. It significantly reduces the need for cleaning tasks by shortening maintenance periods.

Central Lubrication

NORTEK Fluids Technology Central Lubrication Systems offer customer-specific solutions. It makes grease-oil lubrication systems with distributors it develops and produces to be single or double line. It can be controlled 24/7 from PLC screen. It can be designed upon customer request.

Oil Analysis

NORTEK Fluids Technology can analyze your oil 24/7 with oil particle and water measurement devices and offer special solutions based on results.

Rolling Mill Cooling Systems

NORTEK Fluids Technology Roll cooling systems are used in cold rolling plants for steel, aluminum and non-ferrous metals.

API Systems

Training

Need Technical Support?

Our expert team is ready to help with product selection, technical specifications, and custom solutions.

Contact Our Experts